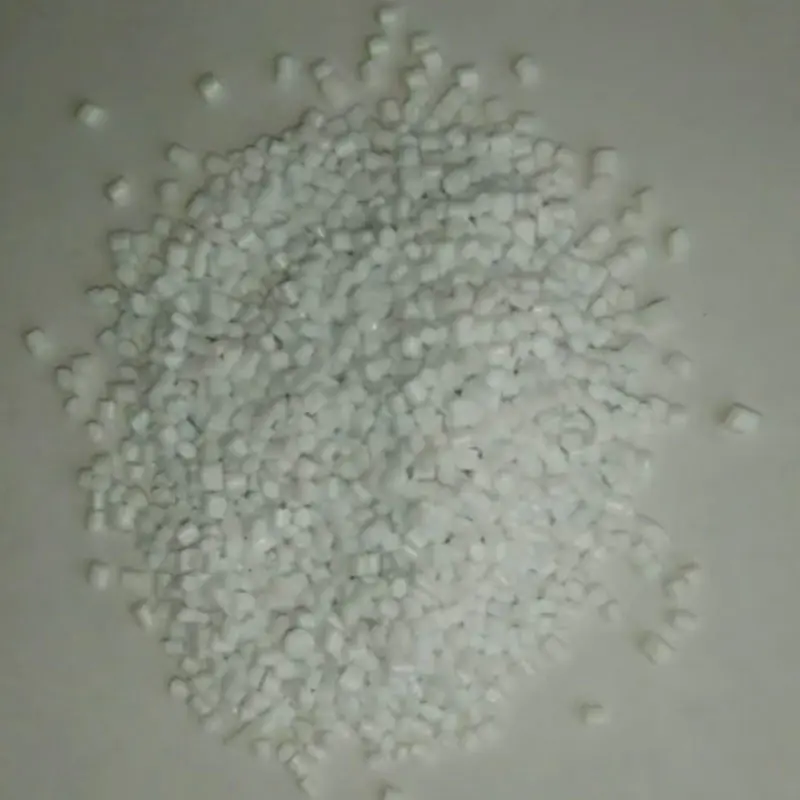

PET chip bottle grade CAS 25038-59-9, commonly known as PET bottle chips, are essential in crafting PET bottles. Derived from Isophthalic Acid, these chips, with the chemical formula C10H8O4 and CAS number 25038-59-9, embody key characteristics:

|

Appearance

|

Small, transparent, crystalline particles.

|

|

Molecular Weight

|

Approximately 192.17 g/mol, contributing to bottle structure.

|

|

Melting Point

|

245-255 °C, ensuring stability during manufacturing.

|

|

Density

|

About 1.37 g/cm³, indicating structural characteristics.

|

|

Clarity

|

Inherent transparency for clear PET bottles.

|

|

Chemical Resistance

|

Excellent resistance to chemicals for product integrity.

|

|

Solubility

|

Insoluble in water and most organic solvents, ensuring stability.

|

Enhanced by Isophthalic Acid, these chips play a pivotal role in producing high-quality, transparent PET bottles for diverse packaging needs.

Product Applications:

PET chip bottle grade CAS 25038-59-9 are highly versatile and find extensive applications across various industries:

Bottle Manufacturing: PET chips are the core material for producing transparent and durable PET bottles widely used in the beverage, personal care, and household product sectors.

Textile Industry: These chips play a crucial role in producing polyester fibers, which, in turn, are used to create lightweight, strong, and quick-drying fabrics for clothing, home textiles, and industrial applications.

Food Packaging: PET bottles manufactured from these chips are ideal for packaging food and beverages, offering transparency and preserving product quality. Commonly used for water, soft drinks, juices, and edible oils.

Cosmetic and Personal Care Products: PET bottles from these chips are extensively used for packaging cosmetic and personal care items due to their chemical resistance, ensuring the integrity of the products.

Pharmaceutical Industry: PET bottles derived from these chips are suitable for pharmaceutical packaging, providing transparency for easy inspection and stability for pharmaceutical formulations.

Engineering and Automotive: PET chips have applications in engineering and automotive industries, utilized in manufacturing components like connectors, insulators, and automotive parts due to their mechanical strength and environmental resistance.

Isophthalic Acid-Based Polyester Bottle Chips prove their adaptability and reliability, serving as a fundamental material across a spectrum of industries.

Packaging and Transportation:

PET chip bottle grade CAS 25038-59-9 are securely packaged in industry-standard containers for efficient handling and transportation, ensuring their integrity for subsequent processing.

Pricing:

The pricing of PET chip bottle grade CAS 25038-59-9 is influenced by factors such as chip specifications, quantity, and market conditions. For detailed pricing information and quotes tailored to specific requirements, please contact our sales department.

Q&A (Frequently Asked Questions):

Q1: What are the key physical properties of PET bottle chips?

A1: PET bottle chips exhibit excellent clarity, mechanical strength, and chemical resistance, ensuring high-quality bottles.

Q2: Can PET bottle chips be recycled?

A2: Yes, PET bottle chips are recyclable, contributing to sustainable practices in the packaging industry.

Q3: What is the typical size range for PET bottle chips?

A3: PET bottle chips are available in various size specifications, catering to the diverse needs of bottle manufacturers.

Q4: How is the transparency of PET bottles influenced by these chips?

A4: The high clarity of PET bottle chips translates into transparent bottles, ensuring product visibility for consumers.

Q5: Are PET bottle chips suitable for food and beverage packaging?

A5: Absolutely, PET bottle chips are widely used for producing bottles for food and beverage packaging due to their safety and transparency.

Q6: Can PET bottle chips withstand transportation and storage challenges?

A6: Yes, PET bottle chips are designed to withstand transportation challenges, ensuring they reach manufacturers in optimal condition for bottle production.

For more specific inquiries or custom requirements, feel free to reach out to our customer support team.